Electric Tinning Pot

Last Changed: October 16, 2012

Warning: Use of

this type of home made electric tinning pot carries risks of severe burns

and electrocution. Weld the seams, do NOT braze them as shown in the photos. Brazed seams can fail if you slightly over heat the

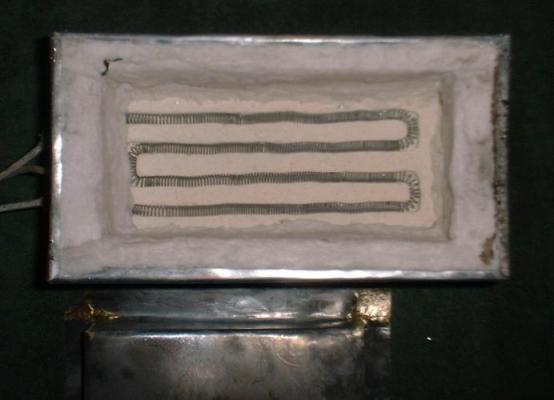

tinning pot

Parts from "All Fired Up!" http://www.kilndr.com/ :

1 soft fire brick 9" x 4.5" x 2.5"

1 square foot of 1" thick Kaowool Ceramic

Fiber Blanket

100 feet of 21ga. Thyssen Resistance Wire (0.845

ohms per foot). This is enough for 3 elements.

2 Porcelain Insulators, T-type

2 Standard Screw Connectors

3 feet of 14ga. High temperature kiln switch box

wire

Parts from McMaster-Carr http://www.mcmaster.com/ :

24" x 24" of 0.036" Type 304 Stainless Steel (2b

finish)

1 male electrical plug

100 Pack of #6 x 3/8" 18-8 stainless steel sheet

metal screws (if you don't already have some)

3' long 3/16" diameter galvanized steel rod

Clip-On Bimetal Thermometer with 1 3/4" dial, 5"

stem, and a temperature range of 200F-1000F

The pot will fit up to 8 pounds of tin which you can buy from Ney

Metals .

1) Cut the 3' long 3/16" diameter rod down so that it's

2' long.

2) 2" from one end of the rod drill a 3/64" hole through the

rod. You may need to file a small flat spot in the rod so the

drill

bit doesn't slip.

3) Cut a 33' length of element wire.

4) Put the end of the rod with the 3/64" hole in a drill and

thread the end of the 21ga. element wire through the hole. Use the

drill

to wind the element wire into a coil. Leave about 3" of unwound wire at

the end of the coil. Put the end of the wire that's through the hole in

the rod out and unwind 3" of wire.

5) Using a router with a 1/4" channel bit make a 9/32" deep groove

in the fire brick with the pattern included below.

6) Very carefully stretch the coil of element wire until it is 30"

long. The coil must be stretched so that all the turns of the coil are

evenly spaced.

7) Insert the coil in to the groove in the fire brick starting at the

middle bend in the groove. Where the coil makes a turn in the groove it

must be stretch out more so that none of the turns in the coil come in

contact with each other.

8) Cut out the pattern for the box.

9) Punch/drill any holes marked on the pattern, make all the bends

shown on the pattern for the box, and use the sheet metal screws to

screw

it together.

10) Remove the screws from the box so that you can open it up enough

to get the fire brick inside it. The ends of the element wire need to

go

through the two Porcelain Insulators Ts with the thin end of the

Insulators

Ts sticking out the two 1/2" holes in the end of the box. Screw the box

back together. (Please note that in the photos of my tinning pot the

thick

ends of the Insulators Ts are shown outside of the pot. I did it that

way

on mine because I had planned to use an 4"x4"x2" electrical outlet box

to enclose the base wires.)

11) Cut the "Kaowool Ceramic Fiber Blanket" into two 2.75" x

9.75" and two 2.75" x 3.25" pieces which line the sides of the

box

above the fire brick.

12) Cut out the pattern for the tin tray.

13) Make all the bends shown on the pattern for the box and weld the

seams so that there are water tight.

14) Cut the 3' of 14ga. high temperature kiln switch box wire into

3 one foot pieces and attach them to the electrical plug. Remember

which

wire is the ground wire.

15) Use a screw with a washer to attach the other end of the ground

wire to the hole marked on the pattern as "ground wire". Use the two

screw

connectors to attach the ends of the two live wires to either end of

the

element wire.

16) Get a power strip with an On/Off switch. With the switch turned

OFF plug the tinning pot into the power strip and plug the power strip

into an outlet.

17) Switch on the tinning pot and check that the heating element coil

heats evenly.

18) Insert the tin tray into the pot and load it with tin. When melting

tin in the tray for the first time a propane torch can help to melt the

tin ingots.

Patterns for

this

project

To control the temperature of the tin you can either:

1) Build a temperature controller box with an electronic temperature controller and thermocouple probe that inserts into the tin to measure the temperature. After reaching the preset temperature the temperature controller will turn the power to the elements on and off with the use of a relay to maintain that temperature.

2) Use a high temperature thermometer to measure the temperature and

manually turn the power on and off to maintain the correct temperature.

Copyright 2012 Craig W. Nadler All rights reserved